Plastic Pellet Making machine

PP HDPE LDPE LLDPE Melting Extrusion Machine | Plastic Granules Making Machine

Plastic Pellet Making machine

PP HDPE LDPE LLDPE Melting Extrusion Machine | Plastic Granules Making Machine

Features at a Glance

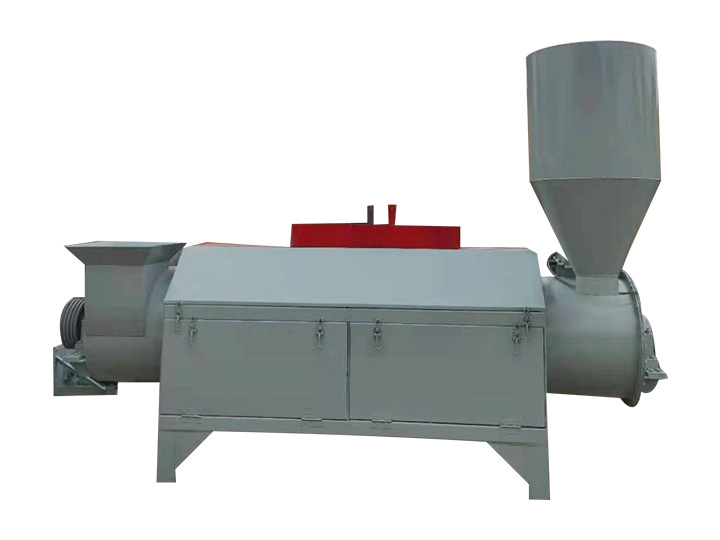

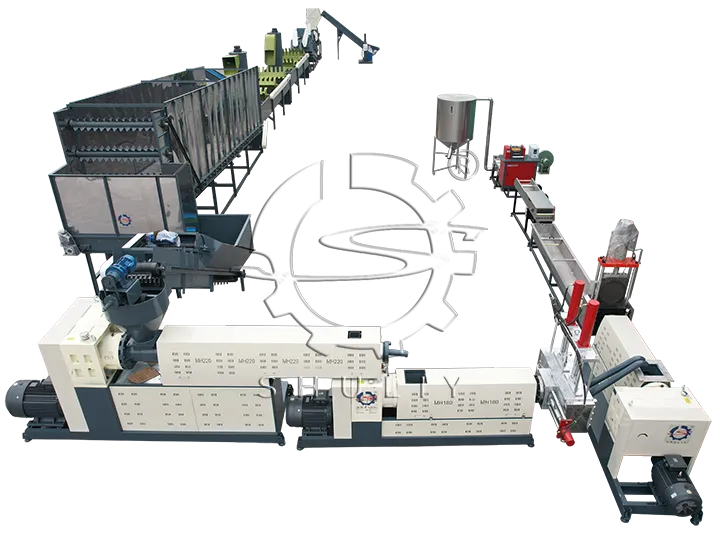

A plastic pellet making machine is a recycling machine for extruding, cooling, and dicing polyethylene (plastic film, lining bag, etc.) or polypropylene (old woven bag, packing bag, tying rope, etc.). It is also called a plastic granulator machine. Plastic granulator machine plays important roles in the plastic recycling granulating line and has a high market value. Therefore, if there is plenty of waste plastic in your place and you want to make a profit from them, you can choose Shuliy plastic pelletizer.

Plastic pellet making machine introduction

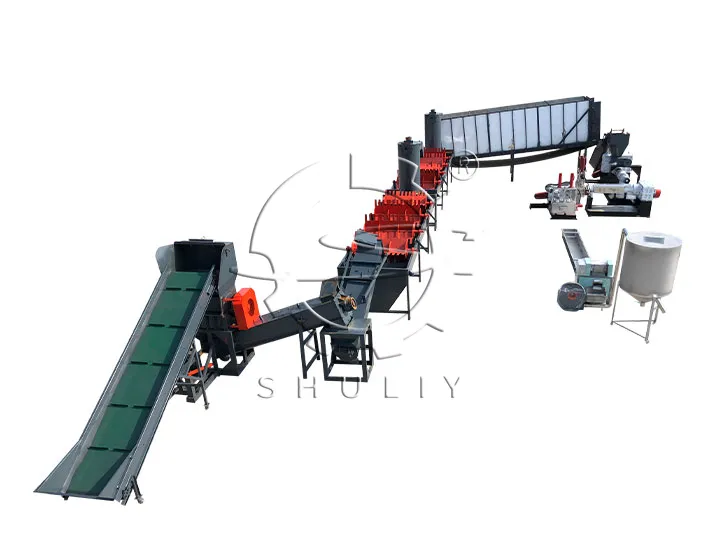

This plastic recycling pellet machine is matched with the crushing and cleaning machine and the pellet cutter. Broken and cleaned plastic can be directly put into extrusion granulation. Simple process, advanced technology, and is suitable for different waste plastics.

Waste plastic granules making machine adopts automatic temperature control and electromagnetic heating, with less electricity, no pollution, and high automation.

Plastic granules manufacturing process

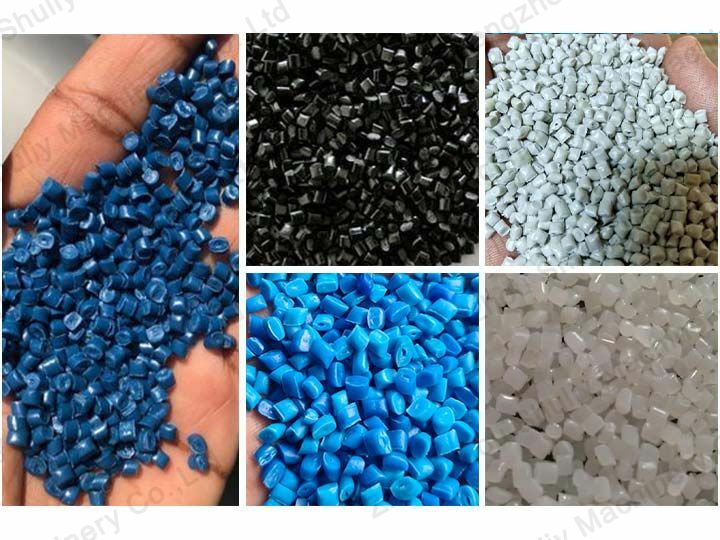

Raw materials and final product of plastic pelletizer machine

The plastic pellet making machine’s applicable raw materials include PP and PE plastic films, cement bags, and plastic hard sheets. The pelletizer is a perfect choice for both posr consumer recycling anf in-house recycling. Before pelletizing, the plastic waste needs to be crushed into small pieces by a plastic crusher. They can be melted and extruded by the plastic extruder. In order to guarantee the quality of the plastic pellets, different materials cannot be mixed. If you have EPS or EPE foam, we also provide related plastic foam granulator.

Read more:

- Recycling solutions for common plastic scrap

- Introduction of shrink film recycling

- Something you need to know about laminated film recycling

- Stretch film wrap recycling and pelletizing

Features of plastic pellet making machine

- The plastic pelletizer machine adopts a special screw design and different configurations. The plastic pelletizing system is suitable for the production of different kinds of plastics for regeneration and color-mixing granulation.

- The high-torque design of the gearbox achieves smooth performance without noise.

- The screw and barrel are specially hardened, with wear resistance, good mixing performance, high output characteristics, vacuum exhaust, or ordinary exhaust port design, which can remove moisture and exhaust gas during the plastic granules manufacturing process.

- Our pelletizers are more stable, the particles are stronger, ensuring good quality.

- The plastic recycling pelletizing machine can process 2-30 tons of waste plastic per day. These plastic scrap are processed into pellets of various colors and then used in various industries.

- Combined with balers and bale openers for large plants, it meets the highly automated needs of large recycling plants.

Energy-saving of plastic recycling pelletizer machine

The main and auxiliary machines are integrated, the installation is simple, the footprint is small, and the performance and price ratio are outstanding. This equipment uses the principle of high-pressure friction uninterrupted heating and uses a multi-function heating mode, and is equipped with a constant temperature system.

The plastic pelletizer machine does not require continuous heating and reduces energy consumption by 30%-40%. Reasonable design of an automatic process for the waste plastic granules machine. Cleaning, crushing, feeding, and pelletizing mechanized flow which is easy to operate for one or two people.

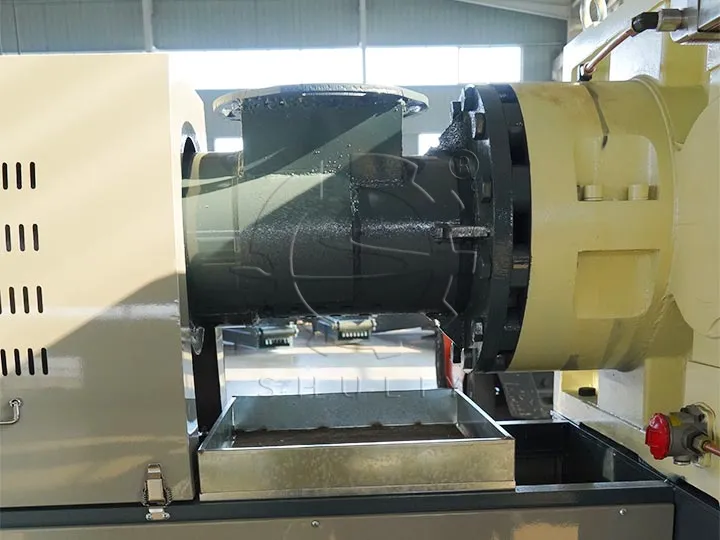

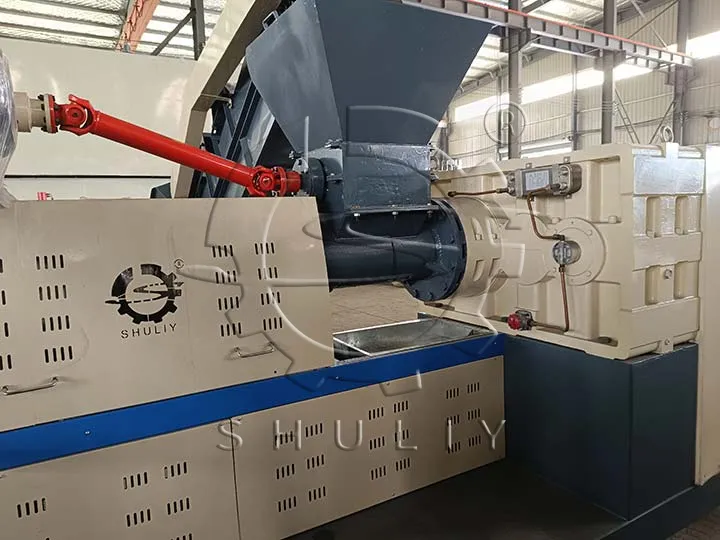

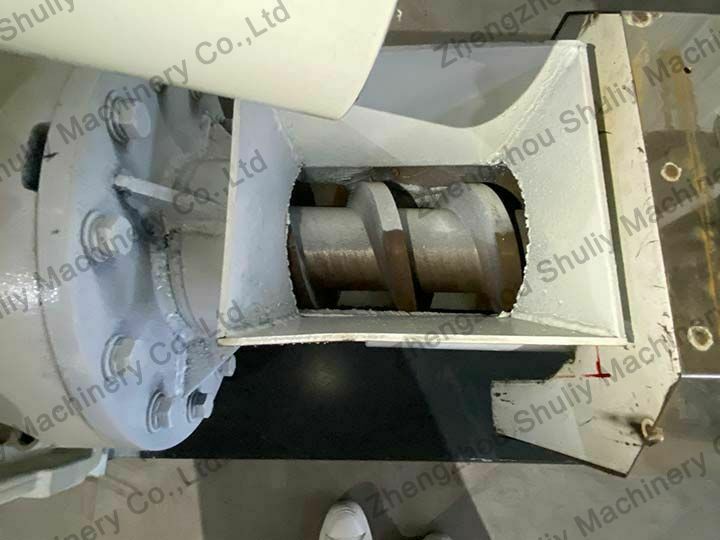

Structures of mother baby double stage extruder machine

This plastic pellet making machine is mainly composed of a feeding port, single screw press, press chamber, heating device, discharge port, mold head, reducer, machine body, base, motor, and other parts. Two-stage is the most common model for recycling plants. According to its structure, we always call the pelletizer a mother-baby double-stage single-screw extruder.

- Screw: It is the most important part of the extruder. Because the pelletizer screw is directly related to the application range and production efficiency. Shuliy mother baby double stage extruder screw is made of high-strength corrosion-resistant alloy steel, which is good enough for most recycling plants.

- Barrel: The pelletizing barrel is a seamless metal tube, it is made of alloy steel, heat-resistant, pressure-resistant high strength and solid.

Shuliy pelletizing barrel and screw with the realization of the plastic crushing, softening, melting, plasticizing, exhaust and compaction. Generally, the length of the barrel is 15:1 of its diameter, so that the plastic can be fully heated and melted.

This plastic extrusion pelletizer is the main plastic recycling machine of the plastic recycling pelletizing line and can handle a variety of materials. But the recycling machines that handle different materials are not the same. Their appearance is similar, but the diameter of the internal screw, the distance between the screw and the barrel wall, and the length of the screw are all different. They all need to be adjusted according to the material. Therefore, one recycling machine cannot handle multiple materials.

How does plastic granules manufacturing machine work?

A plastic recycling granulator is used to melt and extrude plastics of various materials. The extruded plastic is cooled and cut into plastic particles. These particles can be used for secondary production to make new plastic products.

- First, turn on the plastic granules making machine.

- Secondly, observe the operation of the granules machine, and put it into use after there is no abnormal sound or vibration.

- Before use, it is necessary to preheat the recycling machine so that it can melt the plastic. If the temperature is too high, the melted plastic will turn black; if the temperature is too low, the plastic will not melt.

- Put the crushed material into the feeding port of the plastic granulator machine, and add a forced feeder for plastic film material to prevent the recycling machines from not feeding.

- The material melts in the squeezing chamber and is pushed out continuously along with the squeezing screw. The material from the main engine will enter the auxiliary pelletizer again for secondary melting and extrusion.

- The material from the outlet can be put into the cooling tank for cooling and cut into small granules by a pellet cutter machine. Shuliy also provides water ring pelletizers.

Video: How does a plastic granulator work?

Parameters of plastic pellet making machine

The following models are just our hot sale ones, the model of the plastic granules making machine is named by their screw diameter. If you don’t know how to pick the model, welcome to consult us.

The pelletizing machine SL-125 is not our smallest model, likewise, SL-200 is not our pelletizer with our largest output. For more models feel free to leave your requirement on our message form, our market manager Ella will contact you within 24 hours.

| Model | SL-125 | SL-150 | SL-180 | SL-200 |

| Screw diameter | 125mm | 150mm | 180mm | 200mm |

| Main shaft speed | 50-70/min | 40-60/min | 40-50/min | 40-50/min |

| Main motor | 22+1.5lw | 30+1.5kw | 45kw | 75kw |

| Capacity | 3t/day | 5t/day | 7t/day/ 24h | 380kg/h |

Extrusion pelletizing system

(1)Screw

The screw is the main part of the plastic pelletizng system. The quality of the screw is directly related to the application range and efficiency of the plastic extruder. The screw is made of high-strength corrosion-resistant alloy steel.

(2)Barrel

A barrel of a plastic pellet making machine refers to a metal cylinder that is made of alloy steel or composite steel pipe lined with alloy steel. This steel has the characteristics of high heat resistance, high compressive strength, Strong wear-resisting, and corrosion resistance.

The barrel is used in conjunction with the screw to achieve pulverization, softening, melting, plasticizing, venting, and compacting of the plastic. It also conveys the rubber to the molding system continuously and uniformly. Generally, the length of the barrel is more than 15 times its diameter. The main function of it is to make the plastic fully heated and fully plasticized.

(3)Hopper

A cutting device is installed at the bottom of the hopper to adjust and cut the material. The side of the hopper is equipped with a sight hole and a calibration metering device.

(4)Die head

The die head of the plastic granules making machine has three types, including an electric gear die head, hydraulic die head and automatic slag filter. The function of the machine head is to transform the rotating plastic melt into a parallel linear motion so that the plastic melt is introduced into the mold sleeve evenly and smoothly, and the plastic is given the necessary pressure for molding.

A split sleeve is usually placed to ensure that the plastic flow path in the recycling machine head is reasonable and eliminates the dead angle where the plastic accumulates. Besides, a grading ring is usually also provided to eliminate pressure fluctuations during plastic extrusion. Mold calibration and adjustment devices are also installed on the machine head to adjust and correct the concentricity of the core and the mold sleeve.

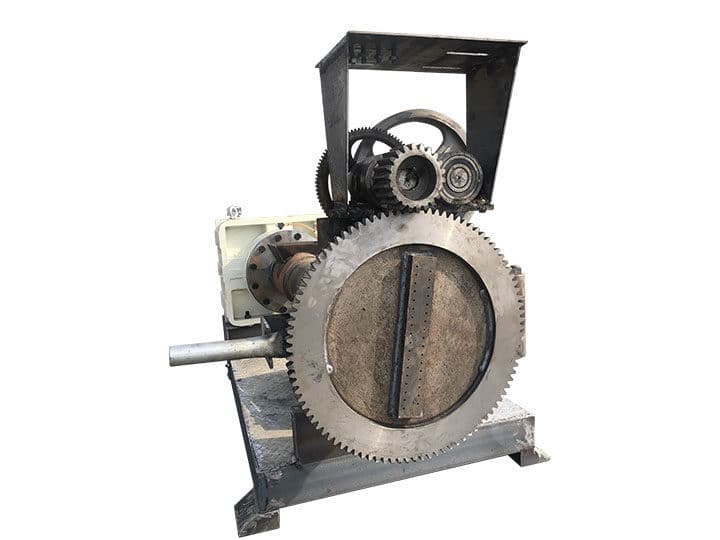

Transmission system of PP PE granule extruder

The function of the transmission system of the plastic granulator machine is to drive the screw. It also can provide the torque and speed required for the screw during the extrusion process. In general, the drive system consists of a motor, a reducer, and bearings.

Heating device of plastic pellet making machine

Heating is an important condition for plastic granulation processes. Shuliy plastic pelletizer can provide three different heating methods.

Heating device

Plastic pellet making machine is generally heated by electricity which is divided into resistance heating and induction heating. The heating piece is distributed in the machine body and the parts of the plastic pelletizer machine’s head. The heating device heats the plastic in the cylinder from the outside, and the heated plastic is in a liquid state, which is convenient for processing.

There are mainly three heating methods for plastic recycling machines. They are electromagnetic heating, ceramic heating, and iron heating. Customers can choose different heating devices according to their demands. Also, customers can consult our sales manager about choosing heating methods.

Cooling device

The cooling device is set to ensure that the plastic is in the temperature range required by the process. Specifically, it is to eliminate the excess heat generated by friction when the screw rotates. It can avoid too high temperatures producing some problems, such as plastic decomposition, plastic burning, or plastic molding difficulties.

Why choose Shuliy plastic pellet making machine?

A good plastic pelletizer is very important for the whole recycling, which influences the quality of the final plastic pellets. Therefore, how to choose a good machine is worth to be considered.

- Reducers, die heads, and motors of Shuliy granulator machines are all the highest equipment currently on the market.

- Our plastic recycling pellet machine can be customized according to customer requirements or raw materials. Such as the diameter of the screw press, the heating method, the die, the material of the screw press, etc.

- Our company has rich production experience in plastic recycling. There are many different plastic materials on the market. Many plastic granulator manufacturers do not understand the material, and mistakenly believe that all the internal structure of the machine is the same. So the machine-made seriously affects the output and quality of the final product.

How does the peculiar smell come from when the plastic pelletizer is granulating?

The old customers who bought our plastic recycling pellet machine have reported to us that there is a strange smell after the waste plastic granulator is granulated. Is the machine damaged? Is this smell harmful to the body? What is the main reason? After experiments and research on this problem, our factory has discovered the cause of the peculiar smell of the plastic granulator.

Plastic pellet making machine shipped to Ghana

Congratulations! Our company has exported a set of plastic pelletizing machines to Ghana. The customer in Ghana bought our plastic pelletizer machine for recycling waste plastic film. Our sales manager Sunny introduced them to our plastic pelletizer and the suitable heating method.

Finally, the customer chose the main pelletizer to be heated with the ceramic heating method and the second pelletizer to be heated by a heating coil.

Plastic granules machine sent to Germany

Germany is one of the best countries in the world in waste separation and recycling, with a world-leading waste recycling rate of about 65%. Encouraged by the national policy, our German customer decided to start a plastic recycling business last year, mainly recycling some waste plastic films and so on. Therefore, he started to invest some plastic recycling machines.

After looking at our website, the customer contacted the account manager and finally chose our plastic pellet making machine. In addition, they bought the whole plastic recycling line, including plastic crusher, pellet cutter and storage bin.

Read more successful stories of our global clients:

- Oman client uses Shuliy HDPE pelletizer machine to reprocess crate scrap

- Shuliy engineer helped Nigerian HDPE recycling plant install pelletizing machines

- Shipment and order details of Ethiopia client’s recycling machines

- Two-stage pelletizer for Iran logistic turnover crate recycling

- Client’s feedback from Côte d’Ivoire! HDPE granules manufacturing process

Inquires for plastic granules manufacturing machine

To acquire the latest plastic granules manufacturing machine price, send us a message by using the form on our website.

Our project manager will send you the machine details & price in 24 hours.

Why is plastic granules making machine so popular?

Plastic pollution has always been a worrying issue for people around the world. As a convenient material, plastic brings convenience to the public and brings us a huge safety problem. Waste plastic contains toxic substances. If burned, they will be detrimental to the air. If buried, they will influence the quality of the groundwater. Shuliy plastic pelletizer machine has been popular iin South Africa, Nigeria, Soudi Arabia, etc.

If the waste plastic is not properly disposed of, it is likely to result in a large-scale disaster. The plastic recycling pellet machine plays an important role in the environmental problem. Professional equipment can reuse some of the plastic waste to reduce the risk of air and water.

Hot Product

Waste tire recycling line | rubber granules making machine

The waste tire recycling line uses advanced tire…

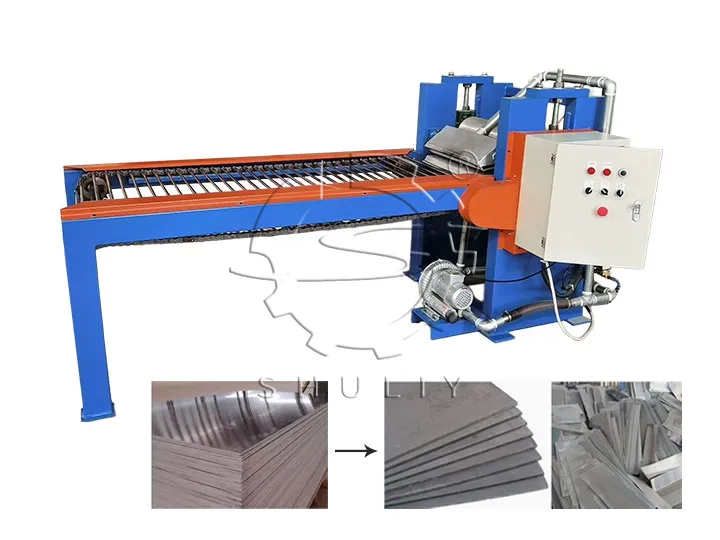

Shuliy SL-Series ACP Recycling Machine

Scrap Aluminum Composite Panels (ACP) from construction and…

Plastic pellet dehydrator

The plastic pellet dehydrator is used to remove…

EPS/Styrofoam Densifier Hot Melting Machine

Descriptions of the styrofoam densifier The styrofoam densifier…

Fibre Shearing Machine | Fiber Shredder for Cutting Waste Cloth

The fibre shearing machine can cut worn-out clothes…

Precision Rubber Block Cutter: Dual Models for Tire Recycling Lines

In a semi-automatic recycling line, the process of…

PET bottle flakes hot water washing tank

The hot water washing tank is suitable for…

Plastic Film Recycling Machine

The plastic film recycling machine is highly efficient…

Waste Plastic Crusher for PP LDPE HDPE Recycling

A waste plastic crusher cuts plastic materials into…