Tire Strip Cutting Machine for Efficient Tire Recycling

Tire Strip Cutting Machine for Efficient Tire Recycling

The processing of scrap tires requires reliable and efficient equipment. Positioned as a crucial second step in a semi-automatic recycling line, following the tire sidewall cutter, the tire strip cutter’s performance directly impacts the throughput and profitability of the entire operation. This machine is engineered to convert whole tire treads into uniform strips, preparing them for the subsequent cutting and granulation stages.

Engineered for Performance and Durability

Our Tire strip cutting machine is not just another piece of tyre recycling equipment; it is a meticulously designed solution based on core engineering principles for waste tire processing. The following analysis of its technical data demonstrates its capability.

Robust Construction for Unmatched Stability

The operational stability of a cutting machine is paramount. With a net weight of 850 kg and a compact footprint of 1.3m x 0.8m, the machine’s mass is concentrated in its heavy-duty steel base and frame. This substantial weight is a deliberate design choice to dampen vibrations during the cutting of steel-belted radial tires, ensuring consistent strip width and significantly extending the machine’s service life.

Optimized Powertrain for High-Torque Cutting

Effective cutting of tire rubber, embedded with steel wires, demands high torque, not high speed. Our system utilizes a 5.5 KW motor paired with a robust gear reducer, delivering a final blade speed of 45 r/min. This low-speed, high-torque configuration provides the necessary shearing force to process tough materials without stalling or overheating. While the theoretical capacity reaches 1000 kg/h, a practical and sustainable operational output is estimated at 600-800 kg/h, depending on tire type and operator efficiency. This makes it an ideal tire slitter machine for steady production.

Cost-Effective Blade System

Consumable costs are a major factor in recycling operations. The dual circular knives on this machine are forged from a specialized hard alloy steel (e.g., Cr12MoV or equivalent). The key economic advantage is that the blades support repeated grinding. Instead of costly replacements, the cutting edges can be re-sharpened to restore performance. A single sharpening cycle is rated to process approximately 1200 steel-wire tires (passenger car tire equivalent), making it a highly economical choice for semi-auto rubber powder production line.

Anatomy of the Tire Strip Cutting Machine

Understanding the function of each component reveals the machine’s robust design.

- Motor: Provides the primary power for the entire system.

- Reducer: Crucial for converting the motor’s high speed into low-speed, high-torque output.

- Gear & Protection Cover: Transmits power to the main axis while the cover ensures operator safety.

- Upper & Down Knife: A pair of hardened alloy circular blades that perform the shearing action.

- Main Axis: A solid, hardened steel shaft that holds the knives and withstands immense cutting forces.

- Base: The heavy foundation that provides stability and absorbs operational vibrations.

Technical Specifications at a Glance

| Parameter | Value | Notes |

|---|---|---|

| Model | Tire Strip Cutter | Standard model |

| Motor Power | 5.5 KW | Optimized for torque and energy efficiency. |

| Capacity | 1000 kg/h (Theoretical) | Actual output varies by material. |

| Axis Speed | 45 r/min | Low speed ensures high torque for tough materials. |

| Dimensions (LWH) | 1.3m * 0.8m * 1.65m | Compact design for easy integration. |

| Weight | 850 kg | Indicates heavy-duty, stable construction. |

| Strip Width | 3-5 cm (Adjustable) | Standard for subsequent processing machines. |

Applications and Customization

This Tire strip cutting machine is an essential component for various recycling facilities:

- Tire Recycling Plants: As a core machine for producing TDF (Tire-Derived Fuel) or rubber mulch.

- Rubber Powder Production Lines: Pre-processes tires into manageable strips for fine grinding.

- Tire Pyrolysis Pretreatment: Reduces tire size to meet the specific in-feed requirements of pyrolysis reactors.

For clients processing oversized materials, such as large truck tyres or OTR (Off-The-Road) tires, we offer customization services. As a direct manufacturer, we can engineer larger, more powerful versions of this machine to meet your specific operational needs.

Contact us today to discuss your project requirements and receive a detailed quote and technical consultation for the Tire strip cutting machine that best fits your production goals.

Hot Product

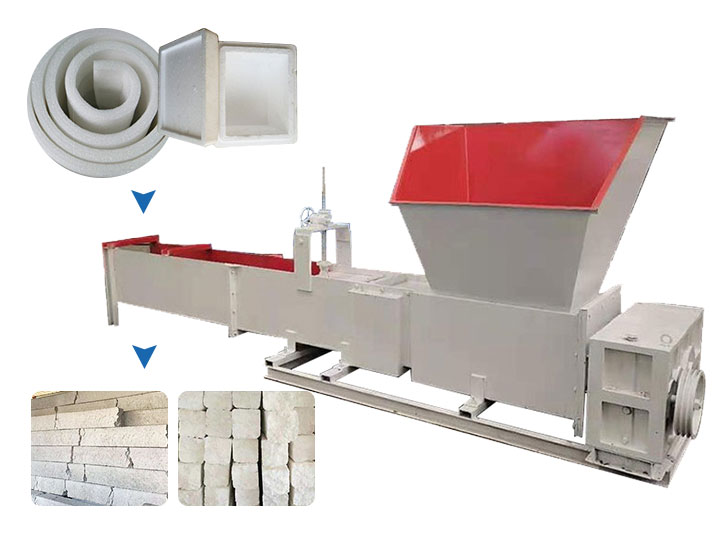

Vertical EPS foam compactor | Styrofoam recycling densifier

Vertical EPS foam compactor is one of the…

Manual powder coating booth

The manual powder coating booth is a small…

PET Plastic Bottle Recycling Machine

Our complete PET bottle recycling line is an…

Cotton Waste Recycling Machine | Garment Rags Tearing Machine

The cotton waste recycling machine is mainly used…

Vertical type dewatering machine for waste plastic films

A vertical type dewatering machine is used for…

Plastic Film Granulator for PP PE LDPE LLDPE Recycle

The plastic film granulator by Shuliy is a…

Waste Plastic Crusher for PP LDPE HDPE Recycling

A waste plastic crusher cuts plastic materials into…

EPS/Styrofoam Densifier Hot Melting Machine

Descriptions of the styrofoam densifier The styrofoam densifier…

Pioneering waste plastic water ring pelletizer

Due to the advantages of the water ring…